Overview

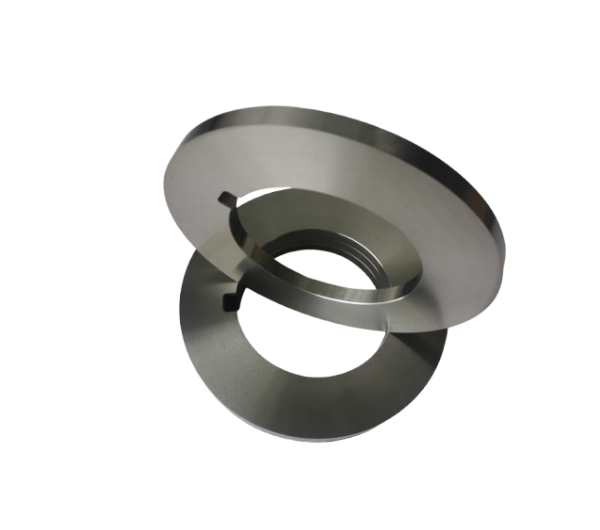

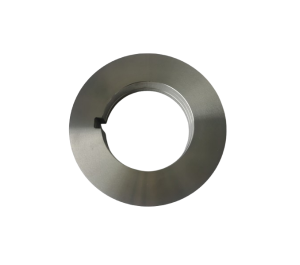

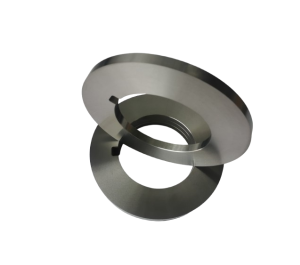

High‑performance tungsten carbide slitting knives engineered for precision slitting of electrical silicon steel (GO/NGO), nickel strips, stainless steel, aluminum, copper and titanium foils. Mirror‑polished cutting faces and micron‑level tolerances ensure burr‑free, straight edges under high‑speed slitting conditions.

Key Features

Performance

- Mirror‑polished edges for burr‑free cutting

- Cryogenic stress‑relief for dimensional stability

- Extended lifetime & reduced line downtime

Material Options

- Tungsten carbide grades: MC15/ MC10X/MC12U

- Coatings available for anti‑adhesion in nickel slitting

Typical Tolerances

- Thickness: ±0.001 mm

- Outer diameter: ±0.0025 mm

- Parallelism: ≤ 0.003 mm

- Surface finish: Ra 0.02–0.05 μm (mirror)

Why Carbide Instead of HSS?

- Wear Resistance × 3–10 vs HSS

- Edge Retention for ultra-thin silicon steel and nickel strips

- Thermal Stability and adhesive wear resistance

- Surface Quality: mirror-polished carbide reduces friction

- Lifecycle Cost: fewer regrinds and changeovers

- Process Capability: micron-level tolerances for high-speed lines

Applications

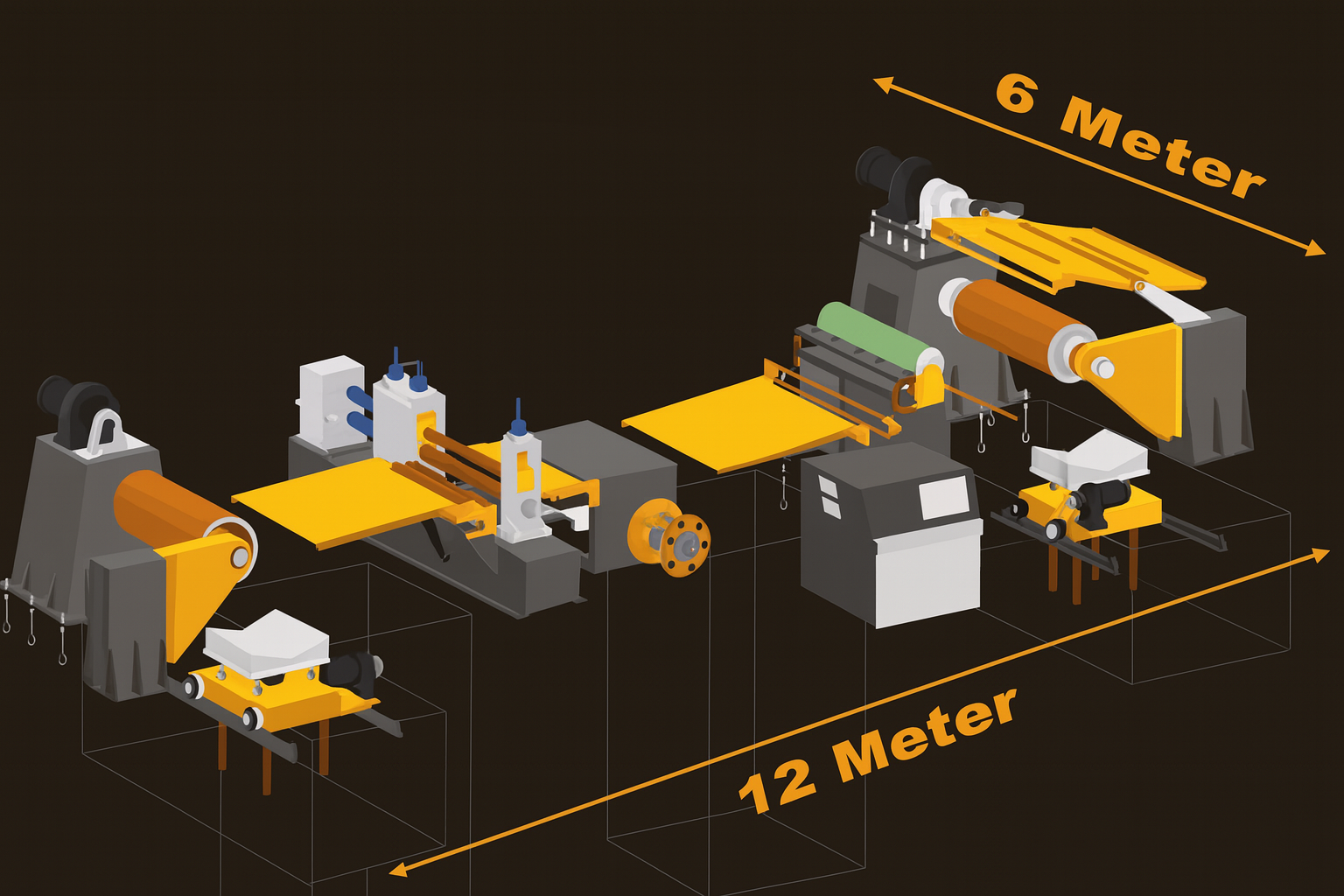

Slitting Lines

Seamless integration with international high‑speed slitting lines. Proven performance in electrical silicon steel and nickel strip production.

- Electrical silicon steel: clean edges, insulation coating intact

- Nickel strips: high sharpness & anti‑adhesion cutting

- Other materials: stainless steel, aluminum, copper, titanium, composites

How It Works

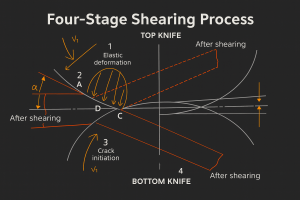

Rotary slitting follows a four‑stage shearing mechanism between the top & bottom knives:

- Elastic deformation

- Plastic deformation

- Crack initiation

- Complete fracture

Precision‑ground knives maintain stable force distribution, yielding straight, burr‑free cuts with minimal material deformation.

Typical Specification (Example)

- Dimensions OD 215.9 mm × ID 127.0 mm × Thickness 12.7 mm (customizable)

- Hardness HRA 89–92 (up to 93 with selected grades)

- Upper/Lower Set Matched pairs available; custom chamfer/radius options

- Compatibility silicon steel 0.23–0.35 mm; nickel strips; stainless & non‑ferrous foils

Order Guide

We primarily accept custom manufacturing based on customer drawings or samples.

If no drawings or samples are available, please provide the following information for quotation and configuration:

-

Required dimensions (OD × ID × Thickness) & quantity

-

Material type and thickness range to be slit

-

Upper/lower knife configuration and target edge finish

-

Line speed, strip width range, and machine model

-

Any coating, chamfer, or special radius requirements

Contact

Phone: +86 13762270918 | Email: [email protected]

Updated 2025-08-22 07:07 UTC. Specs shown are representative; custom tolerances available upon request.