Description

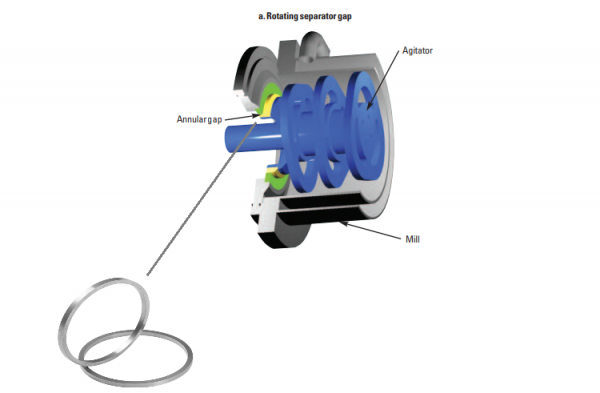

The Static-dynamic Separator Rings is installed in the outlet system of bead mill which included a outer ring and a inner ring as a set .

They are been used to separate the grinding media from the grinding products. Usually the inner diameter of outer ring been designed as a chamfer or a sharp edge.

The normal size

- for 5-30L bead mill is ( OD 100 X ID 90 X T 10mm /OD 120 X100.8 X4mm)

- for 50- 60L bead mill is ( OD 115 X ID 105 X 10 / OD 138 XID 115.8 X 4mm).

The characteristics of tungsten carbide

- high thermal conductivity values

- low coefficients of thermal expansion

promote the efficient removal of heat and provide dimensional stability at higher operating temperatures

- Produce almost any design efficiently and economically

- Several grade types(nickel-bonded grades that provide superior corrosion resistance

- Exact tolerances, finishes, and carbide grade that your application demands.

Application

Specification

| Name | The Static-dynamic Separator Rings |

|---|---|

| Other Name | Wear rings |

| Material | Tungsten carbide, hard metal, hard alloy ,Widia,tungsten steel |

| Composition | Tungsten carbide with cobalt or nickel binder |

| Density | 12.6 to 14.8 g/cm3 based on different grade |

| Hardness | HRA79 to HRA 91.5 based on different grade |

| Features,advantages | Wear resistant, corrosion resistant, impact resistant , high fracture strength , high hardness |

| Size ranges | OD ≤ 800mm X ID ≤ 700 mm X H ≤ 400mm |

| Finish | As Sintered / Polished , OEM as request. |

| Applications | As the key wear part installed in bead mills ,sandmills and other grinding machines that applied in coating industry. |

| Applications(Use for ) | The environments required high wear resistance, good toughness, and excellent corrosion resistance. |

Call us today or email to [email protected] to discuss your requirements. Our personal service begins as soon as we answer the phone or email.