Description

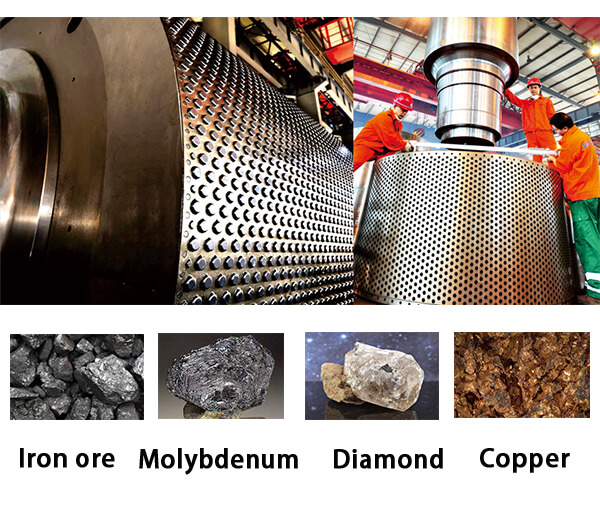

HPGR is an energy-efficient crushing equipment used to reduce particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them. This forces the rocks against each other and compresses the feed’s density to 80% of its solid volume, exceeding its compressive strength with equal pressure being applied to particles of all sizes. HPGR is widely used in grinding cement clinker, limestone, bauxite, iron ore..

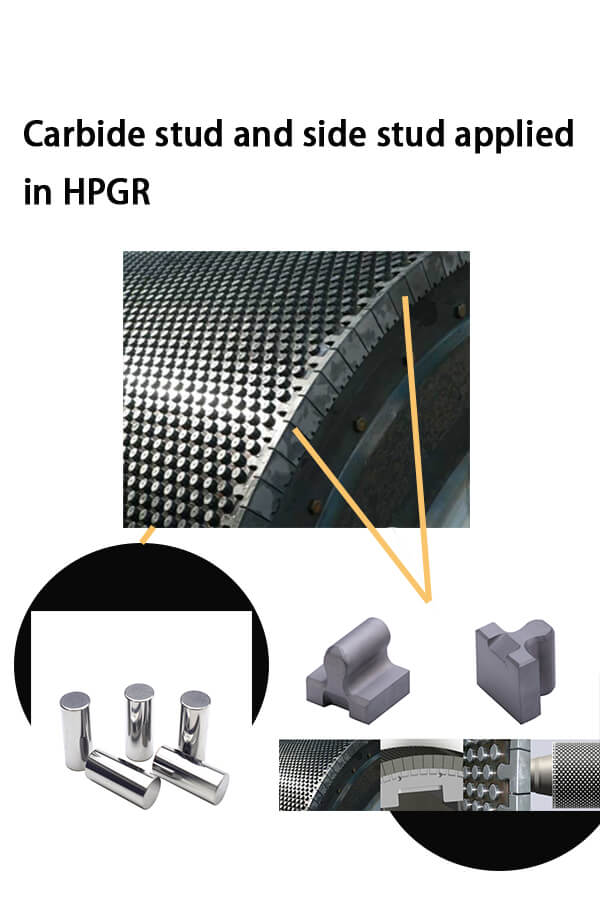

Why TC Studs roller?

There are 3 main types of core components of the HPGR: PTA layer roller surface, centrifugal casting composite roller surface, stud roller surface. the disadvantage for first two types is that the roller surface will be subjected to severe impact due to the direct contact of the roller with the material under the action of strong extrusion force (generally 50-300MPa) The abrasive grains and furrows wear, and at the same time, the roller surface will produce squeeze pits. These accumulated pits will cause the fatigue wear of the roller surface material, which seriously affects the normal operation of the equipment.

For stud roller surface, the base body is made of high-strength alloy steel, which has high hardness after quenching and tempering. The wear-resistant layer is made of tungsten-cobalt hard alloy studs and inlaid on the body. Generally up to HRC67 or higher, the hardness is much higher than that of the PTA layer roller surface and the centrifugal casting composite roll surface, and the matrix of the stud roller surface can be well protected by the material lining formed. Tungsten carbide studs roller has a service life more than 6 times longer than that of the surfacing roller surface. Energy saving and environmental protection, maintenance-free, high work efficiency, low labor

Why MillerTM TC Studs?

We understand better than anyone what you need in your equipment and we’ve worked closely with people just like you to understand and cater to those needs. We’ve serviced a number of operations worldwide with high capacity High Pressure Grinding Rolls.

Our Advantages:

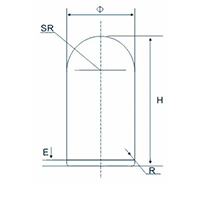

1. Hemispherical top, protect the studs from being destroyed by stress concentration.

2. Round edges, protect the stubs being damaged during production, transportation, installment and using.

3. HIP sintering ensure good compactness and high toughness for the products.

4. Special technology to eliminate the surface stress after surface grinding, and increase the surface hardness at the same time.

5. Grease used on surface of the products to avoid oxidization.

6. Miller has 6 60 t TPA pressing machines and Monthly production of HPGR studs is over 20 metric tons.

7. Miller Carbide has accumulated a number of drawing for different design of studs with Hemispherical top, flat top, conical top,round edges.etc. Drawing of tungsten carbide studs can also be provided by Miller, as a professional manufacturer specialized in tungsten carbide studs manufacturing for 11 years, we have professional engineers to make the drawing per customer’s requirement:

- with product size, we can provide drawing.

- with sample delivered to us, we can provide drawing.

- with picture of product, we can provide drawing.

Grade Information

Grades below are exclusive grades we developed for HPGR. Good wear resistance and high strength are suitable for metal smashing with high working efficiency.

| Grade | Hardness (HRA) | Bending Strength (≥N/mm 2 ) | Density (g/cm 3 ) | Coercivity (kA/m) | WC + Other Binders(%) | Cobalt (%) |

|---|---|---|---|---|---|---|

| YG15C | 85.0-86.5 | 2500 | 13.9-14.0 | 4.5-6.5 | 84.7-85.3 | 14.7-15.3 |

| YG20 | 86.0-87.5 | 2450 | 13.4-13.6 | 8.0-11.0 | 79.6-80.3 | 19.7-20.4 |

| YG15 | 87.0-88.5 | 2800 | 13.95-14.15 | 7.0-10.1 | 85.2-85.6 | 14.4-14.8 |

| MK650 | 87.8-90.0 | 2950 | 13.95-14.15 | 8.0-10.50 | 85.1-85.5 | 14.5-14.9 |

Other grades can be offered according to customers’ requirement.

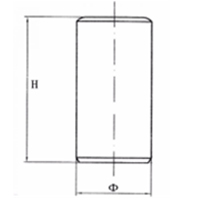

Usual Types and Dimensions of Tungsten Carbide Studs

| H | Ø | Approx Weight (g) |

|---|---|---|

| 50 | 16 | 137 |

| 45 | 18 | 156 |

| 40 | 20 | 172 |

| 40 | 16 | 108 |

| 35 | 20 | 150 |

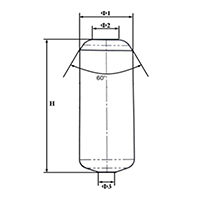

| H | ∅1 | ∅2 | ∅3 |

|---|---|---|---|

| 70 | 21.9 | 11.5 | 5 |

| 60 | 16.5 | 7.5 | 5 |

| 50 | 21.9 | 11.5 | 5 |

| 40 | 15.9 | 7.3 | 5 |

| 35 | 21.9 | 11.5 | 5 |

| ø | H | SR | E X R |

|---|---|---|---|

| 20 | 40 | SR8 | 2xR5.0 |

| 20 | 30 | SR8 | 2xR5.0 |

| 20 | 35 | SR8 | 2xR5.0 |

| 16 | 55 | SR8 | R2.0 |

| 16 | 50 | SR8 | R2.0 |

| 16 | 45 | SR8 | 2xR5.0 |

| 16 | 40 | SR8 | 2xR5.0 |

| 16 | 40 | SR8 | 1xR2.0 |

| 16 | 40 | SR8 | 1X45° |

| 16 | 35 | SR8 | R2.0 |

| 16 | 20.5 | SR8 | R2.0 |

| 10 | 22 | SR5 | R1.0 |

| 10 | 22 | SR5 | R1.5 |

| 10 | 20 | SR5 | R1.5 |

| 8 | 20 | SR4 | R1.0 |

| 5 | 10 | SR2.5 | R1.0 |

Call us today on +86 731 222 800 67 or email to [email protected] to discuss your requirements. Our personal service begins as soon as we answer the phone or email.