Tungsten Carbide Mechanical Seal

-Seal Rings

Rotating shafts of bead mill and other machines require sealing systems to separate pressurized fluids, minimize the entry of debris into the working medium, and prevent the loss of lubricants. A common solution to these problems is the mechanical face seal in which a rotating seal face and a stationary seal face comprise the seal.

Tungsten carbide represents a versatile mechanical seal ring material that is widely applied in all(from PH12 to PH4) but the most acidic environments. Tungsten carbide seals possess a unique combination of high fracture strength and high hardness that minimizes or eliminates the distortion problems under the high pressures or rapid wear in abrasive environments.

Miller™ TC Seal Rings

- Produce almost any design efficiently and economically

- Several grade types(nickel-bonded grades that provide superior corrosion resistance)

- Standard lapped and polished seal faces are flat within 2 helium light bands

Exact tolerances, finishes, and carbide grade that your application demands.

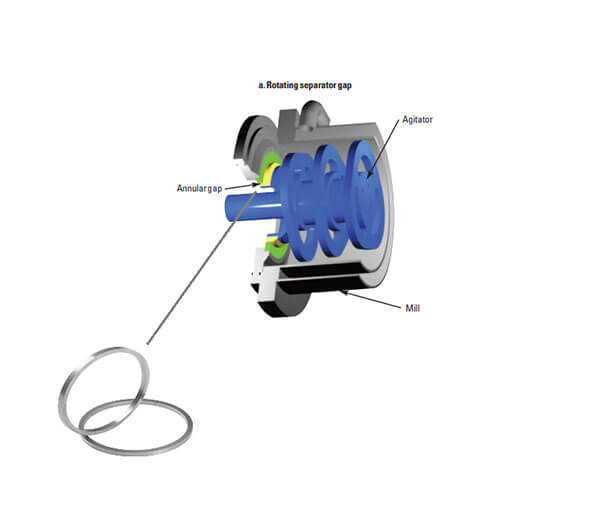

– Static-dynamic Separator Rings

The Static-dynamic Separator Rings is installed in the outlet system of bead mill which included a outer ring and a inner ring as a set.They are been used to separate the grinding media from the grinding products. Usually the inner diameter of outer ring been designed as a chamfer or a sharp edge.

The normal size

- for 5-30L bead mill is ( OD 100 X ID 90 X T 10mm /OD 120 X100.8 X4mm)

- for 50- 60L bead mill is ( OD 115 X ID 105 X 10 / OD 138 XID 115.8 X 4mm)

The characteristics of tungsten carbide promote the efficient removal of heat and provide dimensional stability at higher operating temperatures

- high thermal conductivity values

- low coefficients of thermal expansion

The Static-dynamic ring applied in media separator of bead mill

-Other tungsten carbide wear rings

- Thrust Washers

- Carbide Wear Cutting Rings

- Precision Ground Cylinders

- Rod Mill Rings

- Cemented Carbide Circular Cutters

Thrust Washers

Circular Cutters

TC roll Ring

Specification

| Name | Tungsten carbide rings |

|---|---|

| Other names | Seal rings Seal Facings Mechanical seal faces Tungsten carbide teeth TC rings Concrete pump spares wear plate and cutting ring Tungsten carbide mechanical seal stationary face sleeve Cartridge Seals Component Seals Thrust Washers Carbide Wear Rings Precision Ground Cylinders Mill Rollers Rod Mill Rings Carbide Wire Mill Guide Rollers Cemented Carbide Circular Cutters |

| Material | Tungsten carbide, hard metal, hard alloy ,Widia,tungsten steel |

| Composition | Tungsten carbide with cobalt or nickel binder |

| Density | 12.6 to 14.8 g/cm3 based on different grade |

| Hardness | HRA79 to HRA 91.5 based on different grade |

| Features,advantages | Wear resistant, corrosion resistant, impact resistant , high fracture strength , high hardness |

| Size ranges | OD ≤ 800mm X ID ≤ 700 mm X H ≤ 400mm |

| Finish | As Sintered / Polished , OEM as request. |

| Applications | For Chemical Processing,Dairy Products |

| Beverage Processing ,Marine Services,Oil and Gas Production | |

| Energy Exploration,Environmental Services | |

| Applications(Use for ) | The environments required high wear resistance, good toughness, and excellent corrosion resistance. |

Call us today or email to [email protected] to discuss your requirements. Our personal service begins as soon as we answer the phone or email.