Miller™ Calibration & Chain Carbide Balls

Precision Calibration Solutions for Plastic & Tank Processing Equipment

Miller Carbide supplies high‑precision coated cemented carbide calibration balls and chain ball assemblies designed for industrial calibration, sizing, and inspection systems. Our products are widely used in plastic tank manufacturing, pipe calibration, and rotational molding equipment, where long service life and dimensional stability are critical.

Product Overview

Our Calibration Balls and Chain Ball Systems are engineered for demanding environments involving heat, abrasion, and filled plastics. Manufactured from tungsten carbide (WC) and available with advanced wear‑resistant coatings, these components ensure consistent internal diameter calibration and repeatable measurement results.

Typical applications include:

- Internal diameter calibration of plastic tanks and pipes

- GO / NO‑GO dimensional inspection systems

- Chain‑driven calibration fixtures

- Engineering fixtures and custom calibration tools

Product Range

Your Content Goes Here

-

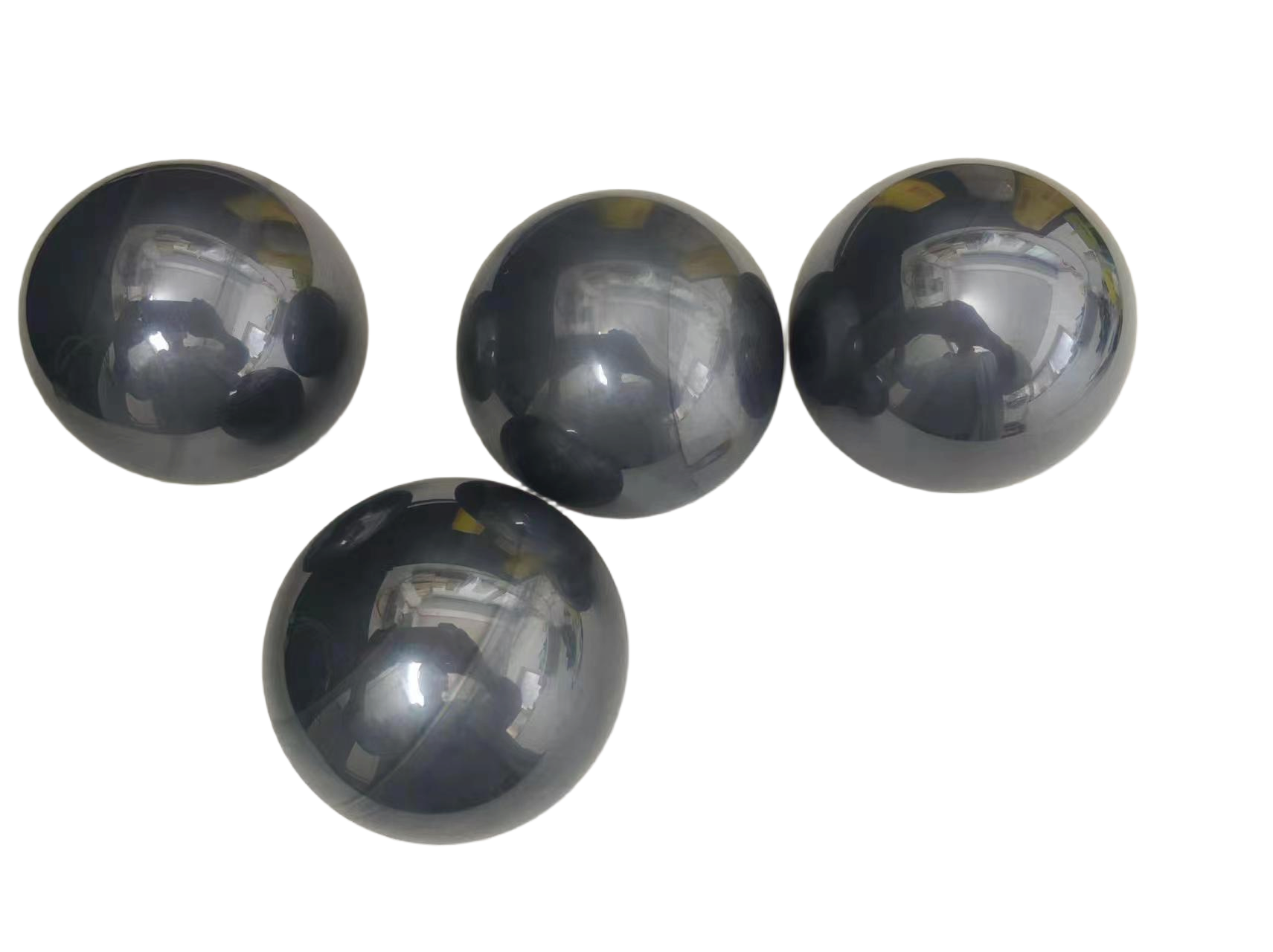

Carbide Calibration Ball

High‑accuracy solid carbide balls used for diameter calibration and inspection.

Available sizes (examples):

- 1″ Calibration Ball: Ø22.05 / 22.10 / 22.15 mm

- 3″ Calibration Ball: Ø72.90 / 72.95 / 73.00 mm

- 4″ Calibration Ball: Ø97.35 mm

- Custom diameters from Ø15 mm up to Ø100+ mm

-

Carbide Chain Ball

Carbide balls integrated with chain systems for calibration of long tubes or enclosed cavities.

Typical configurations:

- WC Chain Ball 3/4″

- WC Chain Ball 1″

- Custom chain assemblies available

- Internal calibration of pipes and containers

- Automated or semi‑automated calibration equipment

-

Pins & Mandrel

Supporting components for calibration fixtures and tooling assemblies.

Examples:

- TC Ball Pins for bending Ø15.5 mm / Ø15.45 mm

- Pins Mandrel 0.5″ TC Ø9.17 mm

- Pins Mandrel 0.75″ TC Ø15.45 mm

These components ensure precise positioning and reliable operation of calibration balls within fixtures.

Materials & Coatings

- Materials: Tungsten Carbide (WC)

- Coatings: TiN coating available

- Hardness: ≥ 2300 HV Superior wear resistance

- Surface quality: Ra ≤ 0.2 μm

Application – Tube Bending Ovality Reduction Calibration

After tube bending operations, ovality deformation often occurs due to material stress and bending forces.

Tungsten carbide calibration balls are used as internal calibration tools to reduce ovality and restore roundness.

Custom Manufacturing

Miller Carbide supports custom designs based on drawings or samples, including:

- Special diameters and tolerances

- Coated or uncoated carbide solutions

- Complete chain ball or fixture assemblies

Our engineering team works closely with customers to deliver reliable calibration components tailored to specific equipment requirements.

Why Miller Carbide

- Over 20 years of cemented carbide manufacturing experience

- Precision grinding and strict quality control

- Stable supply for international industrial customers

- OEM and ODM capabilities

Contact Us

For technical details, quotations, or custom solutions, please contact us

Calibration Balls • Chain Ball Systems • Carbide Precision Components