Overview

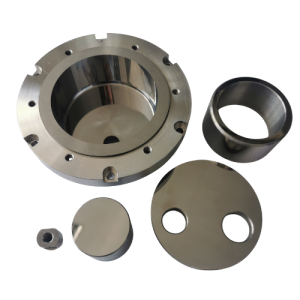

Zhuzhou Miller Cemented Carbide Co., Ltd. manufactures high-performance tungsten carbide grinding sets for vibratory cup mills, ring and puck mills, and disc mills.

Designed for rapid fine grinding of hard and brittle materials, these products are ideal for cement, mining, geology, ceramics, and analytical laboratories.

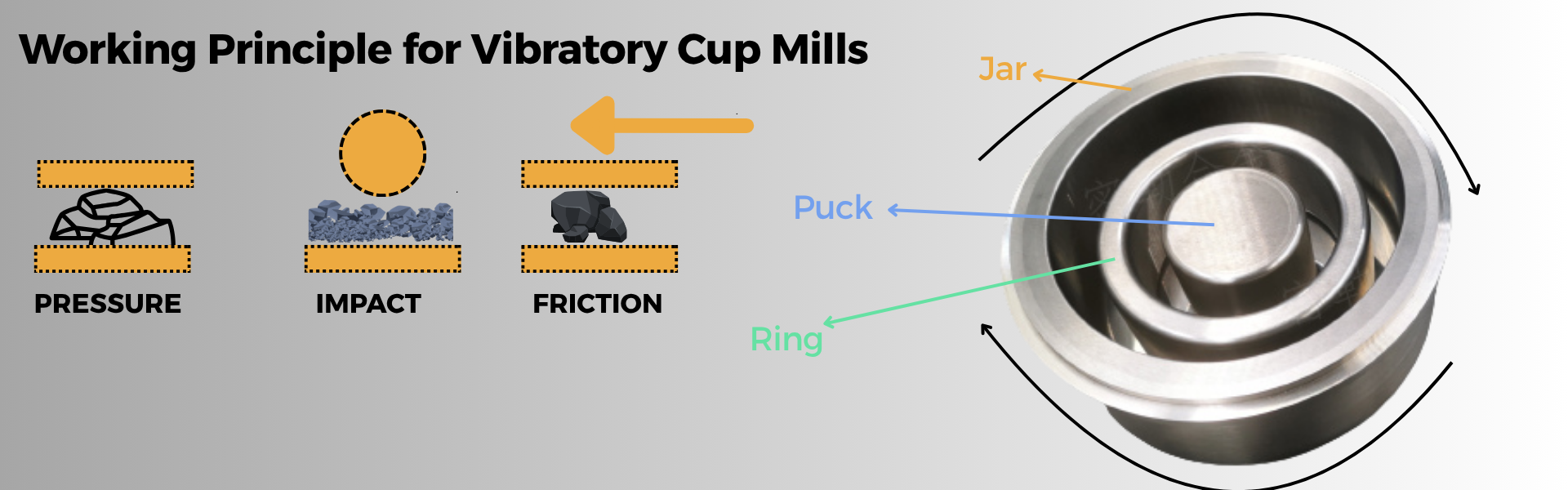

Working Principle

A vibratory cup mill pulverizes materials through high-frequency three-dimensional vibration.

Inside the grinding bowl (jar), the ring and puck move in combined circular and vertical motions, generating pressure, impact and friction that rapidly reduce materials to analytical fineness.

Features & Advantages

✅ Rapid grinding to analytical fineness (≤20 µm)

✅ Uniform and repeatable results

✅ Multiple material options: WC / ZrO₂ / Stainless-Steel + Carbide

✅ Dry and wet grinding modes

✅ Precision-balanced and easy to clean

✅ Customizable to any mill geometry

SPEED

Rapid grinding to analytical fineness (≤20 µm)SPEED

Feed size: ≤ 10–12 mm

Final fineness: ≤ 10–20 µm

Grinding time: 30–180 s

Efficient three-dimensional vibration ensures fast pulverizing of hard, brittle, and fibrous materials to analytical-grade fineness within minutes.

PRECISION

Consistent, reproducible grinding performancePRECISION

Each bowl set is dynamically balanced and geometrically optimized to maintain uniform pressure and motion during operation, ensuring highly consistent particle size distribution and reproducibility across batches.

DURABILITY

Engineered for maximum wear resistance and impact strengthDURABILITY

Made from high-toughness tungsten carbide (MC15 grade) and consolidated by vacuum sintering with HIP densification, the grinding components feature excellent hardness (≈89.5 HRA) and fracture toughness (KIC > 11 MPa·m¹/²), ensuring long service life under high-impact vibration.

Material Options

|

Material |

Characteristics |

Typical Use |

|

Solid Tungsten Carbide (WC) |

Ultra-hard and wear-resistant |

Ores, metals, ceramics, ultra hard material |

|

Stainless Steel Embedded Carbide |

Balanced strength and hardness |

Cement, slag, minerals |

|

Zirconia (ZrO₂) |

Chemically inert, non-metallic |

Oxides, ceramics, soil, purity testing |

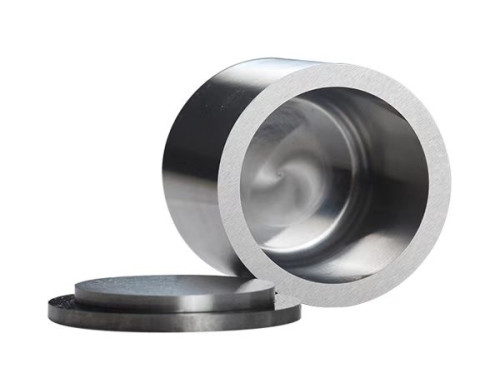

Solid Carbide

Zirconia

SS+Carbide

Technical Insight

Design for Durability and Reliability

From our collaboration with global laboratories, we’ve identified common wear challenges — edge chipping, ring fracture, and stress concentration — and engineered solutions to prevent them:

- Optimized edge radius (R2–R3): minimizes stress concentration and edge chipping.

- High-toughness MC15 carbide: hardness (HRA 86.5) and Bend strength:3200 Mpa.

- Bend strength:3200 Mpa

- Geometry-matched ring, puck, and bowl sets: prevent uneven stress distribution.

- Engineering support: detailed feedback and failure analysis available upon request.

Product Range & Compatibility

Precision-Engineered Grinding Bowl Sets

Miller Carbide manufactures a full range of complete grinding bowl sets — including bowl, ring, lid and puck — compatible with major international vibratory cup mills, ring and puck mills, and disc mills.

Each set is precisely machined and dynamically balanced to ensure perfect fit, efficient grinding energy transfer, and long-term stability during high-frequency vibration.

Available Capacities

| Bowl Capacity | Typical Inner Ø (mm) | Typical Outer Ø (mm) | Height (mm) | Typical Set Configuration |

|---|---|---|---|---|

| 50 ml | 70–75 | 90–95 | 40–45 | 1 puck |

| 100 ml | 90–95 | 110–115 | 45–50 | 1 ring + 1 puck |

| 125 ml | 95–100 | 120–125 | 45–55 | 1 ring + 1 puck |

| 250 ml | 120–130 | 145–150 | 55–60 | 1 ring + 1 puck |

Customized capacities and geometries available upon request to match specific mill models.

Compatible Equipment Brands

Our grinding bowl sets are engineered for direct replacement and full compatibility with equipment from leading global manufacturers, including:

-

FRITSCH – Pulverisette 9 Disk Mill

-

RETSCH – RS 200 / RS 300 Ring and Puck Mills

-

HERZOG – HP-M 1500 and other automatic sample preparation systems

-

Other OEMs – customized according to drawing or sample

Miller’s engineering team can reverse-engineer and reproduce grinding components based on customer drawings, worn parts, or digital models, ensuring precise geometry matching and guaranteed compatibility.

Design Flexibility

-

Custom radius (R2–R3) and geometry to reduce chipping

-

Adjustable clearance and wall thickness for optimal mass balance

-

Optional locking lids, sealing rings, and identification engraving

-

Multiple material pairings (Carbide–Carbide, Steel–Carbide, ZrO₂–ZrO₂)

Performance Guarantee

Every bowl set undergoes:

-

Dimensional and concentricity inspection

-

Ultrasonic density and porosity test

-

Balance calibration before shipment

-

Traceable batch records for material quality assurance

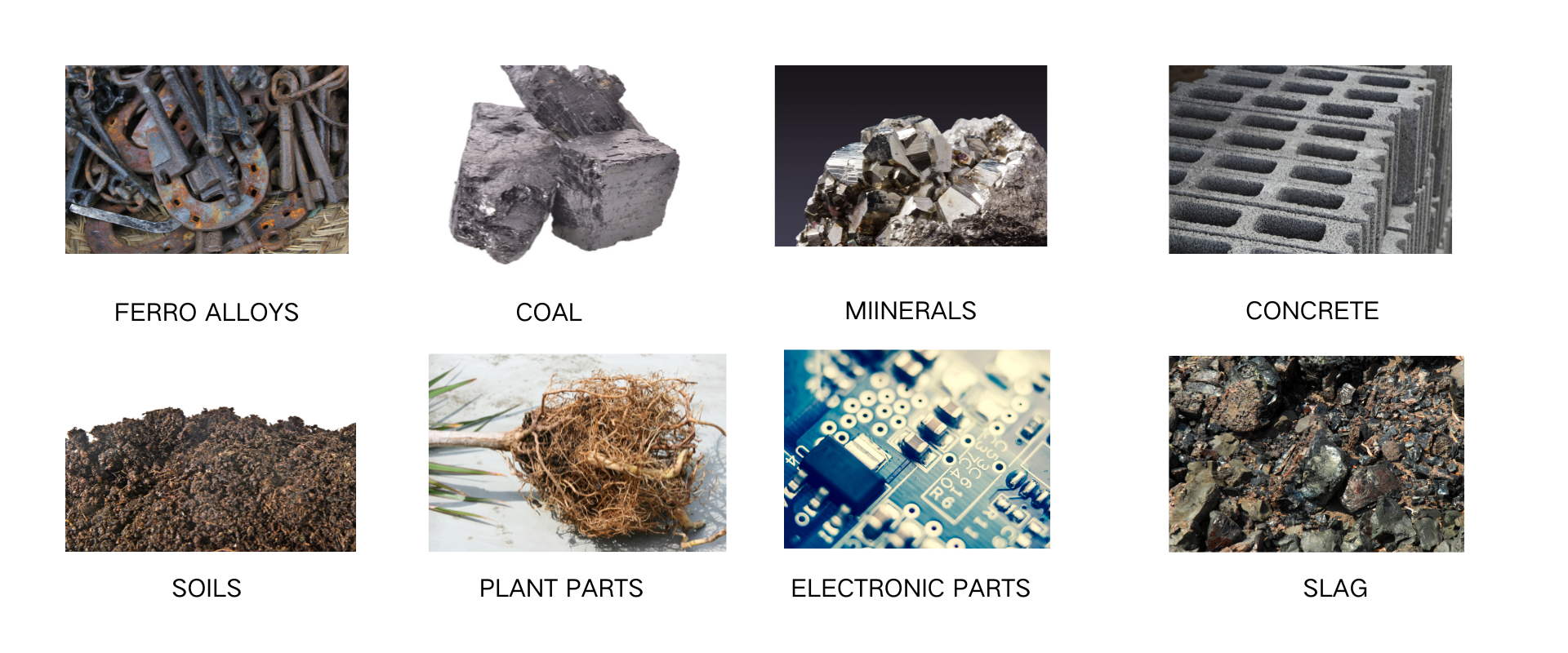

Applications

- Cement and clinker quality control

- Mineral and ore sample preparation

- Ceramic and glass powder testing

- Geological & metallurgical laboratories

- Environmental and material science research

Non-Magnetic Grade Option for Ferroalloys and High-Fe Materials

For materials with very high iron content (Fe > 75%)—such as ferroalloys, pig iron, sponge iron, or metallurgical feedstock—conventional carbide grades may create partial adhesion between the sample and the inner surface of the grinding bowl due to magnetic interaction.

To address this issue, Miller offers an optional non-magnetic carbide grade, specifically engineered to:

-

minimize magnetic attraction between bowl and sample

-

ensure smooth discharge of the ground material

-

reduce manual cleaning and downtime

-

improve consistency and usability during repeated milling cycles

-

prevent unintentional material retention and cross-contamination

This solution is strongly recommended for laboratories that frequently process high-iron, ferromagnetic, or magnetic-reactive samples.

Available upon request. Material formulation remains proprietary to protect intellectual property.

Why Choose Zhuzhou Miller

- 15+ years of expertise in precision tungsten carbide manufacturing

- Proven supplier for global analytical equipment users

- HIP-sintered, fully dense carbide structure

- Dynamic balance & dimensional precision inspection

- Engineering-level customization & technical support

- Reliable global logistics and after-sales service

Ready to upgrade your grinding performance?

Talk to our engineers today.

We will help you select the right material, capacity, and configuration for your application.